Electric System Inspections

Inspecting Your Building with the Latest Infrared Thermal Technology in Columbus, Ohio

How Does an Infrared Electrical Survey Work?

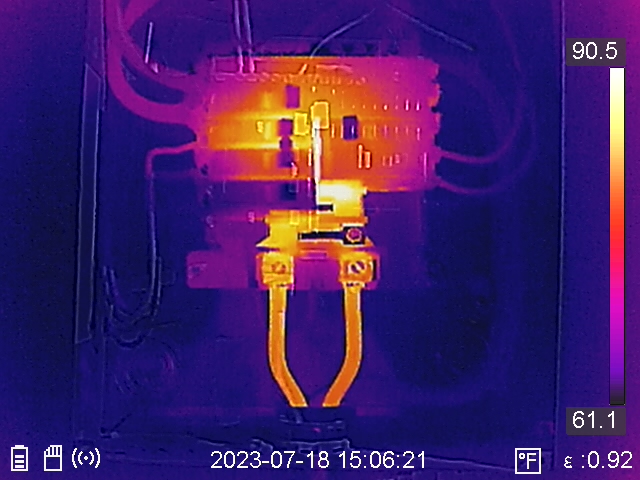

An infrared electrical scan will detect temperature anomalies invisible to the naked eye, picking up problems that can be missed through a purely visual inspection. When equipment is under normal loads, but components show different temperatures, this can indicate an anomaly.

The Bottom Line

Regular inspections are crucial to ensure that your building, whether commercial or residential, serves you well throughout the years by spotting damage early on and preventing it altogether. For your home, our inspectors provide thorough, top-notch, detailed, and simple-to-read infrared inspection reports that are entirely certified. We are certified and experienced inspectors with years of real-world experience. We have used infrared technology to scan hundreds of pieces of electrical equipment. Schools, hospitals, residences, colleges, hotels, and commercial and industrial enterprises are all covered by our services.

The results of our inspections may be fully incorporated into your preventive maintenance program, or we can give your insurance provider a complete and in-depth report.

Reduce Fire Risk with Regular Infrared Electrical Inspections

Securing the safety and integrity of your property is crucial, especially when it comes to preventing fires. Beyond the immediate risks to lives and possessions, fires can inflict substantial financial losses. Harnessing advanced technologies becomes instrumental in effectively addressing this concern.

One such game-changing technology is infrared electrical inspection. This method employs a sophisticated and non-invasive approach to identify anomalies and electrical faults, revolutionizing how we assess and mitigate potential fire hazards in buildings. To grasp its significance, let’s delve into the intricacies of an infrared inspection, exploring both the technical aspects of the technology and the specific focuses of inspectors during the inspection process.

What Is an Infrared Electrical Inspection?

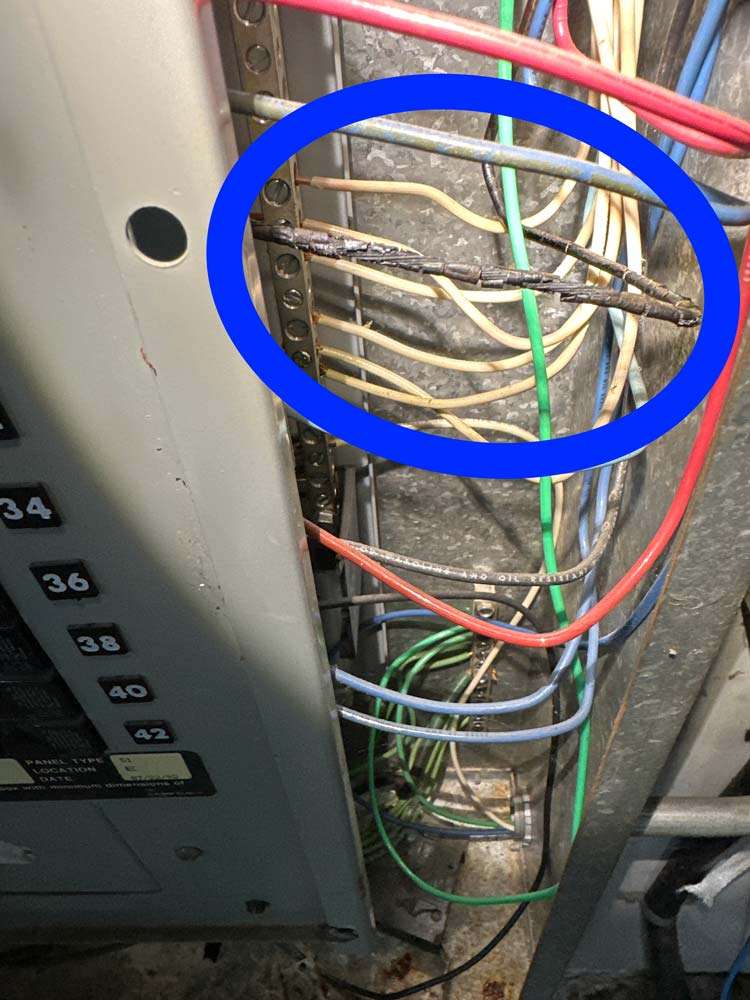

A valuable tool for maintaining the reliability and safety of electrical systems in diverse environments, an infrared electrical inspection employs advanced thermal imaging techniques to identify potential fire hotspots and irregularities. The inspection method meticulously scans various electrical components—particularly in challenging and inaccessible areas—such as breakers, connections, wiring, switches, and motor control centers.

What sets thermal imaging inspections apart are their precision and range of practical benefits. These inspections play a crucial role in reducing unforeseen downtimes, preventing equipment damage, lowering insurance costs, and mitigating the risks of fires arising from both mechanical and electrical issues. They also enhance the safety and efficiency of the workforce.

Protect Your Workplace with an Infrared Inspection

Regular electrical inspections using infrared thermography can protect your workplace by detecting potential issues early on. Advanced infrared cameras are employed to identify anomalies and heat patterns in electrical systems, effectively identifying components operating at elevated temperatures.

Spotting these hotspots early enables timely intervention, stopping problems from growing into more severe issues like equipment damage, electrical failures, or, in the worst case, fire hazards. This proactive strategy not only prevents unexpected downtimes but also lowers the risk of costly replacements or repairs.

Consistent infrared inspections set a standard for the ideal operating temperatures of your electrical equipment. Over time, monitoring deviations or alterations from this baseline helps identify the emergence of potential issues. Armed with this data, you can strategize proactive maintenance and tackle these issues during planned downtime, minimizing disruptions to your facility’s operations.

Regular infrared inspections establish a benchmark for the operating temperatures of your electrical equipment. Over time, keeping an eye on any deviations or changes from this baseline helps catch potential issues early on. With this information in hand, you can plan proactive maintenance and address these concerns during scheduled downtime, ensuring minimal disruptions to your facility’s operations.

Regular infrared inspections help maintain the reliable operation of your electrical systems. Detecting and resolving potential issues in the early stages helps avoid unexpected outages and failures. This proactive approach not only keeps your facility’s operations running smoothly but also minimizes the risk associated with costly downtime.

Your workplace might face various electrical challenges, such as overloaded circuits, loose connections, or faulty equipment, all carrying significant safety risks. Infrared inspections simplify the identification of these issues, enabling you to take corrective actions to minimize and eliminate associated risks. This not only guarantees a safer working environment for everyone but also lowers the chances of electrical accidents, contributing to compliance with safety regulations.

Infrared inspections expose energy inefficiencies in electrical systems—for example, when too much electrical resistance hints at overheating parts, causing energy losses. Fixing these inefficiencies not only trims utility costs and optimizes energy usage but also backs your facility’s sustainability goals.

Routine IR electrical inspections uncover potential electrical issues beforehand to avoid safety hazards or failures. Taking preventive actions and addressing concerns ensures the facility stays safe, ramps up operational reliability, and lessens the risk of costly repairs and unexpected downtimes.

How Does an Infrared Electrical Inspection Work?

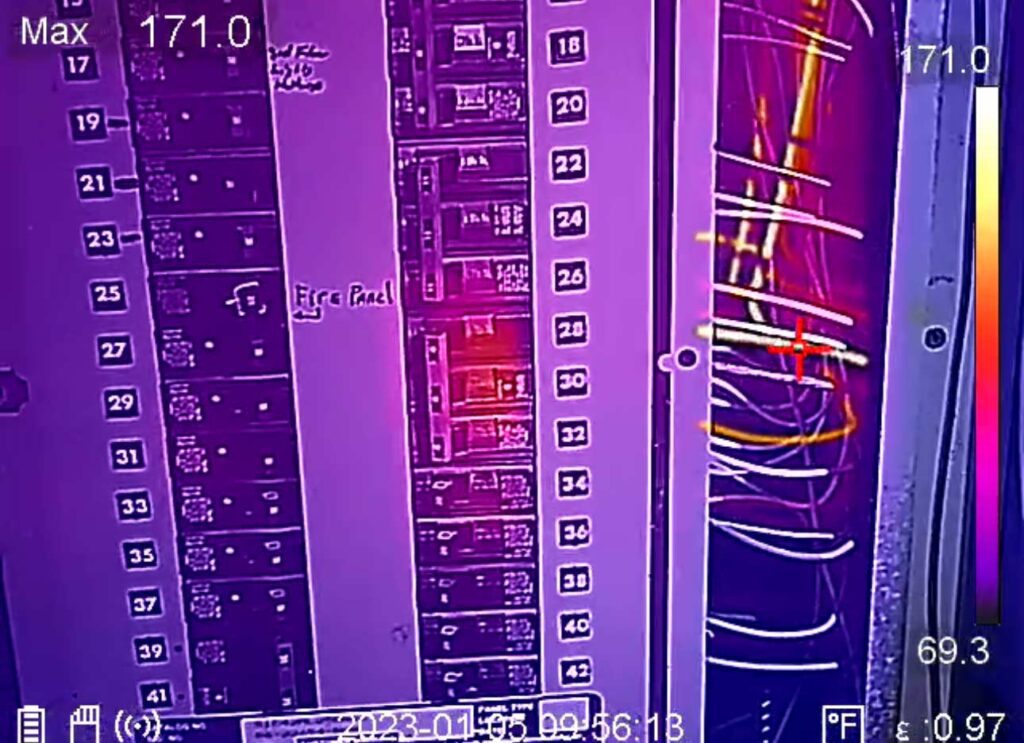

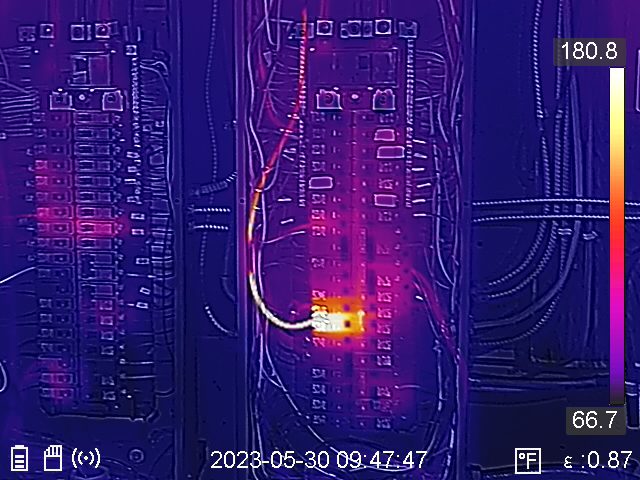

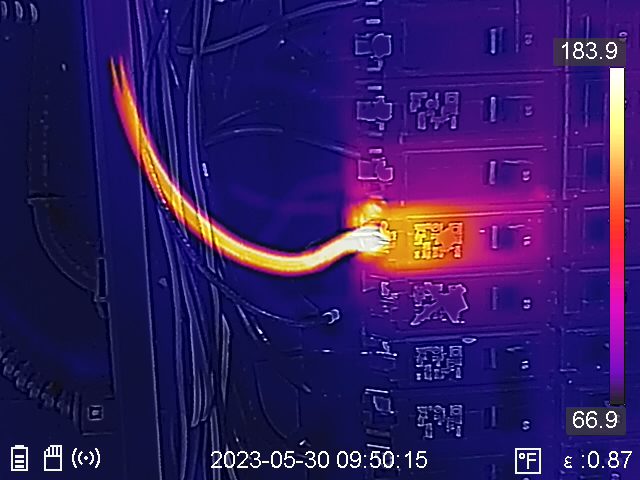

In an infrared electrical inspection, thermal cameras play a crucial role in detecting temperature variations using different levels of infrared (IR) light. Although this light is invisible, it manifests as heat when the intensity is high enough. Infrared radiation, emitted by all objects, serves as a fundamental method of heat transfer.

Inspectors utilize these cameras to scan the electrical system and components while they are operational. This scanning process generates a thermal map, illustrating temperature gradients, overheated areas, and potential anomalies, defects, or fire hazards.

Identifying defects in connections and components causing hot spots is a key aspect of this method. By pinpointing areas with excess heat due to increased resistance, the inspection helps address components before they potentially fail. This proactive approach is essential to prevent damage, productivity loss, and safety hazards.

What Do Infrared Inspectors Look For?

Inspectors focus on crucial electrical aspects:

Identifying abnormal temperature patterns signals potential issues like overloaded circuits, loose connections, or faulty components—increasing the risk of fires.

Inspectors check circuits working beyond their capacity, where excessive heat raises the fire hazard.

Various areas may have loose electrical connections causing heat due to high resistance. Inspectors catch and report on these issues, suggesting replacement or tightening.

Inspectors examine fuses, switches, circuit breakers, and transformers for signs of malfunction, recommending replacements for unusual temperature shifts.

Neglecting these components may lead to electrical failures and, in extreme cases, building fires. Infrared electrical inspection provides vital insights for preventive maintenance, enhancing overall safety.

Invest in Safety

These cost-effective inspections deliver thorough results. Opting for an annual infrared electrical inspection is a wise move to protect against fire hazards, a recommendation backed by the National Fire Protection Association.

The New NFPA 70B

In 2023, the National Fire Protection Association (NFPA) 70B made a significant shift from being a “Recommended Practice” to a “Standard.” This new status includes mandatory language for establishing, implementing, and running an Electrical Maintenance Program (EMP). This change isn’t just a formality; it’s a practical step that adds layers of protection for individuals and enhances the reliability of electrical systems. This move closely aligns with the NFPA 70E Standard for Electrical Safety in the Workplace, stressing that proper installation alone isn’t enough for safety—equipment must also be “properly maintained” according to the manufacturer’s instructions or industry consensus standards.

This standard’s impact isn’t limited; it reaches into the electrical infrastructure of industrial plants, institutional and commercial buildings, and large multifamily residential complexes. While it’s not a legal code like the state-adopted National Electric Code (NEC), NFPA 70B, much like NFPA 70E, sets the minimum consensus requirements for safe electrical work practices. Importantly, the Occupational Safety and Health Administration (OSHA) can use this standard as a foundation for issuing citations.